The device manipulates light to such an extent that it can filter specific colours while still being transparent and could be used in the future to make smart contact lenses.

|

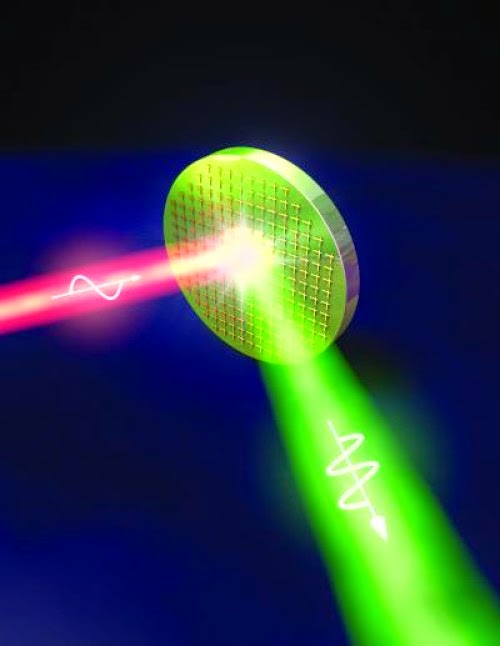

| nanoscale glass structures that filter or manipulate light credit: RMIT/The University of Adelaide |

Using the technology, high-tech lenses could one day filter harmful optical radiation without interfering with vision – or in a more advanced version, transmit data and gather live vital information or even show information like a head-up display.

The light manipulation relies on creating tiny artificial crystals termed “dielectric resonators”, which are a fraction of the wavelength of light – 100-200 nanometers, or over 500 times thinner than a human hair.

The research combined the University of Adelaide researchers’ expertise in interaction of light with artificial materials with the materials science and nanofabrication expertise at RMIT University.

Dr Withawat Withayachumnankul, from the University of Adelaide’s School of Electrical and Electronic Engineering, said: “Manipulation of light using these artificial crystals uses precise engineering.

“With advanced techniques to control the properties of surfaces, we can dynamically control their filter properties, which allow us to potentially create devices for high data-rate optical communication or smart contact lenses.

“The current challenge is that dielectric resonators only work for specific colours, but with our flexible surface we can adjust the operation range simply by stretching it.”

Associate Professor Madhu Bhaskaran, Co-Leader of the Functional Materials and Microsystems Research Group at RMIT, said the devices were made on a rubber-like material used for contact lenses.

“We embed precisely-controlled crystals of titanium oxide, a material that is usually found in sunscreen, in these soft and pliable materials,” she said.

“Both materials are proven to be bio-compatible, forming an ideal platform for wearable optical devices.

“By engineering the shape of these common materials, we can create a device that changes properties when stretched. This modifies the way the light interacts with and travels through the device, which holds promise of making smart contact lenses and stretchable colour changing surfaces.”

Lead author and RMIT researcher Dr. Philipp Gutruf said the major scientific hurdle overcome by the team was combining high temperature processed titanium dioxide with the rubber-like material, and achieving nanoscale features.

“With this technology, we now have the ability to develop light weight wearable optical components which also allow for the creation of futuristic devices such as smart contact lenses or flexible ultrathin smartphone cameras,” Gutruf said.

source ; RMIT news release link : click here

This post is copied from the materials in the RMIT website(news)